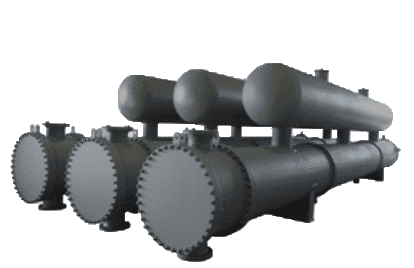

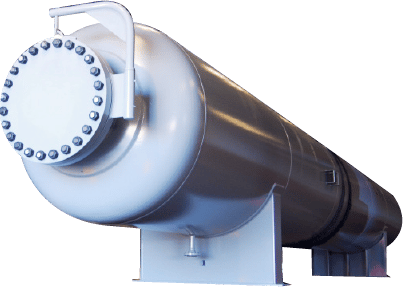

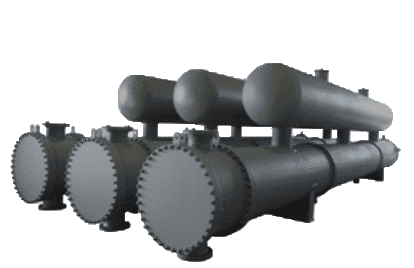

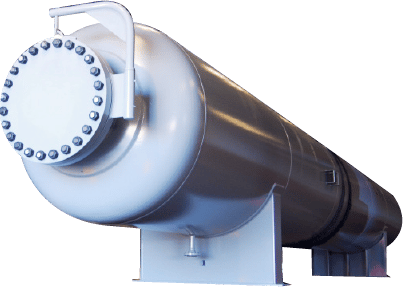

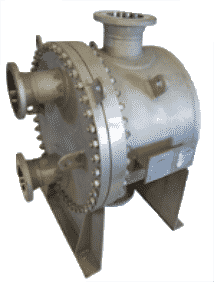

Shell & Tube Heat Exchangers are the most widely used class of heat exchange devices, due to their suitability for a broad range of applications. The refining and petrochemical industries favor Shell & Tube Exchangers because they are robust, reliable and safe.

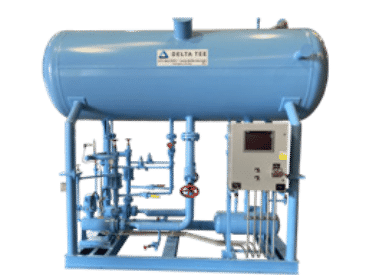

Surge Drums

Suction Accumulators

Intercoolers

Refrigerant Receivers

Coalescing Oil Separators

Liquid Recirculators

Discharge Liquid Traps

Oil Stills

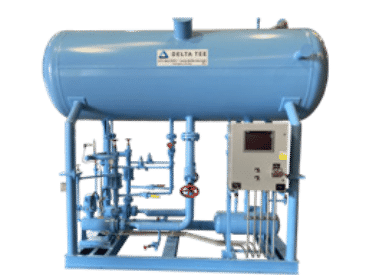

Fully shop assembled and shipped as a single unit, as permitted for transportation. Designed to minimize installation and commissioning time. Full voltage pump motor starters integrated within controller enclosure or in separate enclosure. Soft start starters available upon request.

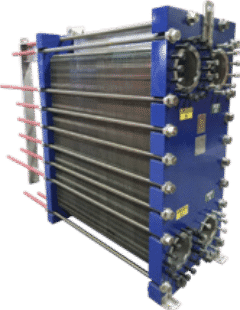

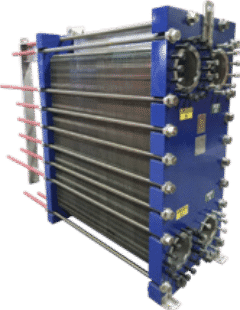

Low refrigerant charge semi-welded corrosion resistant stainless steel cassettes are used as standard.Titanium is available upon request. Dual flow surge drums selected for efficient liquid-vapor separation. Integral oil management system.

Plate & Frame heat exchangers are now common place in industry. They are cost effective and flexible heat exchangers in a small foot print, simple to maintain and highly efficient. The plate packs come as either gasketed, semi-welded or fully-welded assemblies.

Suitable for wide pressure and temperature ranges, they are an ideal solution for both new and retrofit installations. Design parameters can accommodate applications from cryogenic LNG and liquid air service to high temperature gas turbine heat recovery.

Moisture, either as free water or vapor has many detrimental effects in refrigeration systems. It causes rusting and corrosion of metallic components; it also increases the head pressure of the system with subsequent higher operation cost. In systems operating below 32⁰F, it may turn to ice which could plug heat transfer surfaces. The ammonia distiller provides an efficient and economical way of removing water from refrigeration systems.

Lorem ipsum dolor sit amet, consectetuer adipiscing elit, sed diam nonummy nibh euismod Lorem ipsum dolor sit amet, consectetuer adipiscing elit, sed diam nonummy nibh euismod

Lorem ipsum dolor sit amet, consectetuer adipiscing elit, sed diam nonummy nibh euismod Lorem ipsum dolor sit amet, consectetuer adipiscing elit, sed diam nonummy nibh euismod

Lorem ipsum dolor sit amet, consectetuer adipiscing elit, sed diam nonummy nibh euismod Lorem ipsum dolor sit amet, consectetuer adipiscing elit, sed diam nonummy nibh euismod

Lorem ipsum dolor sit amet, consectetuer adipiscing elit, sed diam nonummy nibh euismod Lorem ipsum dolor sit amet, consectetuer adipiscing elit, sed diam nonummy nibh euismod

Lorem ipsum dolor sit amet, consectetuer adipiscing elit, sed diam nonummy nibh euismod Lorem ipsum dolor sit amet, consectetuer adipiscing elit, sed diam nonummy nibh euismod

Lorem ipsum dolor sit amet, consectetuer adipiscing elit, sed diam nonummy nibh euismod Lorem ipsum dolor sit amet, consectetuer adipiscing elit, sed diam nonummy nibh euismod

Lorem ipsum dolor sit amet, consectetuer adipiscing elit, sed diam nonummy nibh euismod Lorem ipsum dolor sit amet, consectetuer adipiscing elit, sed diam nonummy nibh euismod

ASME VIII, DIV. 1

ABS

DNV GL Marine

CRN for all or any province in Canada

KGS-South Korea

PED-Europe

AS-Australia

Migas-Indonesia

Dosh-Malaysia

TEMA

API

NACE

ANSI/IIAR 2

We take great pride in everything that we do, control over products allows us to ensure our customers receive the best quality service.